Nanomolding of metastable Mo4P3

PARADIM Highlight #73

Compared to their natural bulk form, many materials show emergent phenomena and properties when confined to lower dimensions. Nanowires have been of particular interest to realize topological superconductors or topological surface states for low dissipation microelectronics.

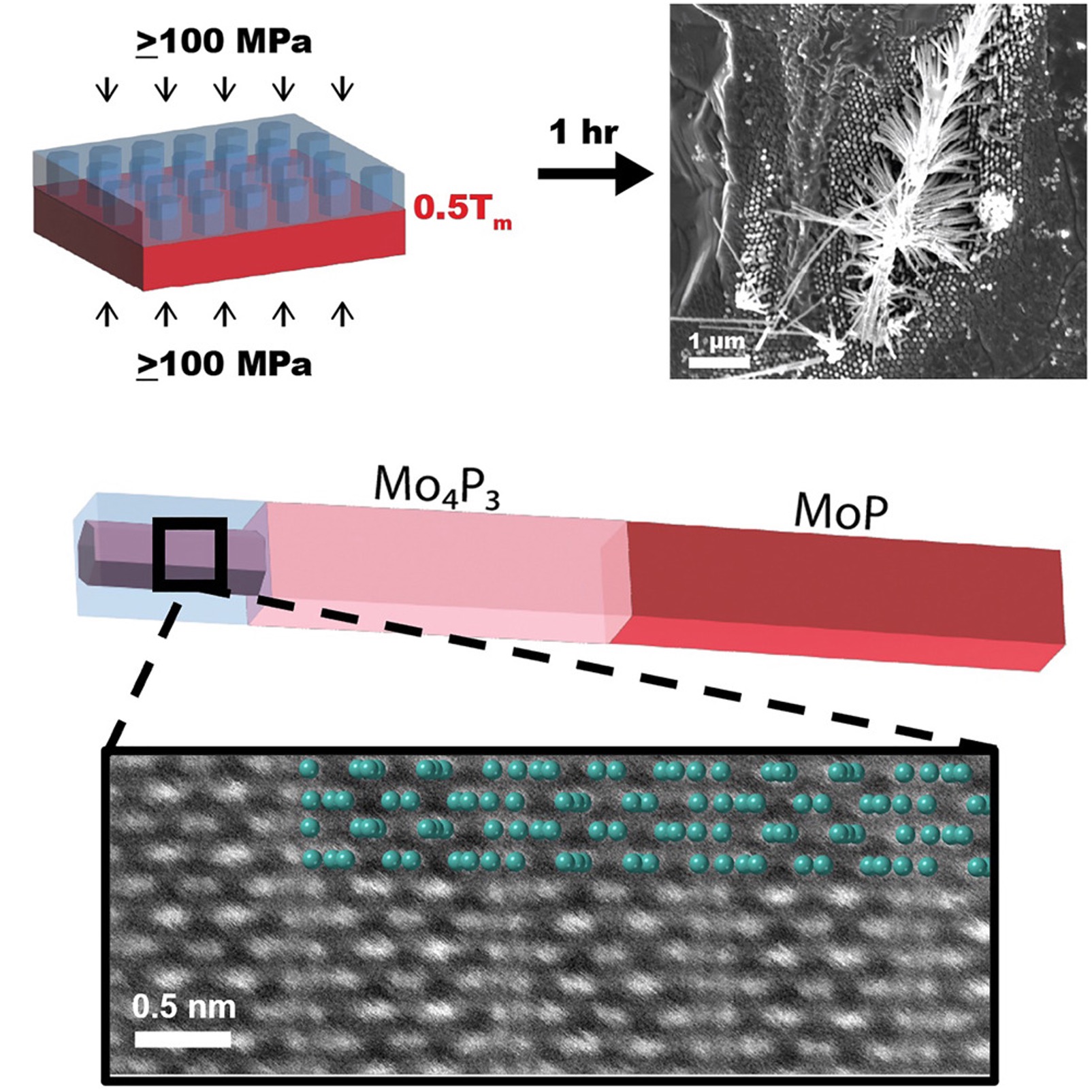

A new fabrication technique to study the vast number of predicted quantum materials is nanomolding, where polycrystalline feedstock material is pressed into a nanoporous mold at elevated temperatures and high pressure. A process that results in single crystalline, defect-free nanowires that can be released from the mold.

Here, an external (now local) group of researchers came to PARADIM’s Electron Microscopy as well as Theory Facilities to characterize nanomolded molybdenum-phosphide nanowires. Using a poly-crystalline feedstock of MoP, the achieved nanowires are of the composition Mo4P3, a phase metastable at room temperature and ambient pressures, demonstrating a new pathway to the nanofabrication of metastable phases. Density functional theory band structure calculations and resistivity measurements indicate that Mo4P3 is a non-topological metal with resistivity values comparable to other molybdenum phosphide compounds.

What has been achieved:

Reduced dimensionality leads to emergent phenomena in quantum materials, and there is a need for accelerated materials discovery of nanoscale quantum materials in reduced dimensions. Thermomechanical nanomolding is a rapid synthesis method that produces high-quality single-crystalline nanowires with controlled dimensions over wafer-scale sizes. Herein, we apply nanomolding to fabricate nanowires from bulk feedstock of MoP, a triple-point topological metal with extremely high conductivity that is promising for low-resistance interconnects. Surprisingly, we obtained single-crystalline Mo4P3 nanowires, which is a metastable phase at room temperature and atmospheric pressure. We thus demonstrate that nanomolding can create metastable phases inaccessible by other nanomaterial syntheses and can explore a previously inaccessible synthesis space at high temperatures and pressures. Additionally, first published density functional theory (DFT) electronic band structure calculations suggest that Mo4P3 is a non-topological metal. Furthermore, our results suggest that the current understanding of interfacial solid diffusion for nanomolding is incomplete, providing opportunities to explore solid-state diffusion at high-pressure and high-temperature regimes in confined dimensions.

Importance of the Achievement:

Thermomechanical nanomolding provides unique capabilities to produce single-crystalline quantum materials confined in one-dimensional geometry at the nanoscale rapidly and at scale while simultaneously providing precision over dimensions and morphology. Further, the nanomolding method was shown to produce metastable phases that are difficult to capture, greatly enlarging the materials discovery space.

Unique Feature(s) of the MIP that Enabled this Achievement:

PARADIM provided access to aberration-corrected scanning transmission electron microscopy (STEM) and 4D STEM, which was critical in determining the correct phase of the molded nanowire, as well as DFT calculations and theory support to understand the electronic properties of the metastable Mo4P3.

The work was initialized through a PARADIM user proposal from Yale University prior to relocating of the user’s group to Cornell University.

In the News:

Molding of nanowires spurs unanticipated phases - Cornell Chronicle

Full reference:

M.T. Kiani, Q.P. Sam, G. Jin, B. Pamuk, H.J. Han, J.L. Hart, J.R. Stauff, and J.J. Cha, "Nanomolding of Metastable Mo4P3," Matter, 6, 1894-1902 (2023)

Acknowledgments:

We acknowledge the support of the National Science Foundation Metals and Metallic Nanostructures program for TMNM (DMR 2240957), Semiconductor Research Corporation for transport measurements (nCORE IMPACT), and Gordon and Betty Moore Foundation for 4D STEM experiments (EPiQS Synthesis Investigator Award). Q.S. acknowledges support from the NSF Graduate Research Fellowship Program. Characterization of the nanowires and DFT calculations were made possible by the Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM) supported by NSF Cooperative Agreement No. DMR-2039380, Cornell Center for Materials Research (CCMR) Shared Facilities supported by the NSF MRSEC program (DMR-1719875), and Cornell Nanoscale Facility (CNF) supported by NSF grant No. NNCI-2025233. TEM sample preparation was performed on a Helios FIB at the CCMR facilities supported by NSF (DMR-1539918).