Digital Light Processing of Dynamic Bottlebrush Materials

highlight

Achievement

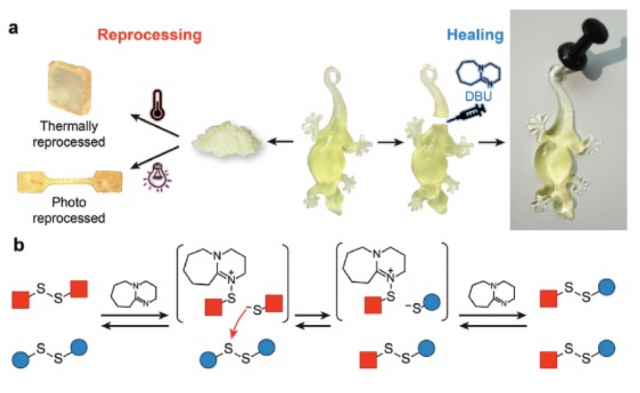

A new class of 3D printing resins that generate super-soft, dynamic, and self-healable elastomers, based on natural building blocks (α-lipoic acid) was developed. These elastomers can be 3D printed via digital light processing (DLP) under mild conditions using commercially available printers and convenient exposure conditions. The resulting materials are crosslinked bottlebrush networks that can undergo dynamic disulfide exchange when exposed to ultraviolet light or elevated temperatures, facilitating reprocessing and post-fabrication healing.

Importance of the Achievement

Bottlebrush elastomers have attracted significant attention as a class of super-soft 3D printing materials, due to their low module values that resemble those of biological tissue and muscle. However, current processing strategies have been limited to molding or extrusion-based 3D printing. The novel materials developed in this paper, expand the range of applications for bottlebrush elastomers by making them available for light-based 3D printing. Moreover, these materials establish a simple design strategy for the preparation of DLP resins from cheap and bio-derived starting materials, leading to printed objects that can be reshaped and healed after experiencing damage, extending the lifecycle of the printed material.

Unique Features of BioPACIFIC MIP that Enabled this Achievement

This work was performed on the Lumen X printer in the BioPACIFIC MIP Additive Manufacturing facility. The Lumen X enables printing under near-UV illumination for high resolution and fidelity. BioPACIFIC MIP also provided financial support for materials and researchers through the Fellows program.